Alispar

Alispar Nosings and Treads are designed to take heavy foot traffic and are suitable for use on external stairs where a high degree of slip resistance is required, even in wet conditions.

They are manufactured to order from high quality tensile aluminium and come fully assembled and drilled for fixing

Typical applications are Railway Station Footbridges and Subways, Hospitals, Schools and High Rise Housing blocks.

Technical Specification

- High tensile aluminium extruded to B.S. 1474 in 6063 T6.

- Front rows of abrasive available in yellow powder coat to highlight step edge.

- 6mm radius to front edge complies with section 2.2.7 of the Code of Practice for Disabled Passengers issued by the Office of the Rail Regulator.

- Colours: Black, Red, Blue, Green. Yellow, Brown.

- Full installation service available nationwide.

- Typical applications: Railway Stations, Hospitals, Schools, Subways - any heavily trafficked external staircase.

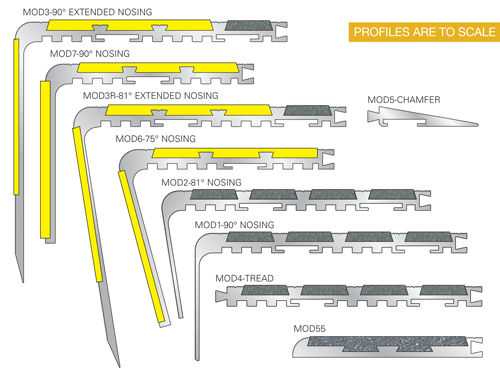

MOD1

90° nosing available in mill finish or yellow powder

coated aluminium. Interlocks with MOD 4 and MOD

5 sections.

View MOD1 technical diagram (pdf)

MOD2

81° nosing available in mill finish or yellow powder

coated aluminium. Interlocks with MOD 4 and MOD

5 sections.

View MOD2 technical diagram (pdf)

MOD3

90° nosing with extended riser incorporating 55mm

yellow or white tonal variation strips. Interlocks with

MOD 4 and MOD 5 sections.

View MOD3 technical diagram (pdf)

MOD3R

An 81° rakeback version of the MOD3.

View MOD3R technical diagram (pdf)

MOD4

90mm wide body section can be used in multiples to

cover full tread and landing depth. Interlocks with

MOD 1/2/3/55 and MOD 5 sections.

View MOD4 technical diagram (pdf)

MOD5

Chamfer section for use on top and landing treads.

Interlocks with MOD 1/2/3/4/55 sections.

View MOD5 technical diagram (pdf)

MOD55

Stair tile replacement nosing, with 55mm tonal

variation infill. Interlocks with MOD 4 and MOD

5 sections.

View MOD55 technical diagram (pdf)

MOD6

75° nosing with riser incorporating 55mm yellow or white tonal variation strips. Interlocks with MOD 4 and MOD 5 sections.

View MOD6 technical diagram (pdf)

MOD7

MOD7 90° nosing with riser incorporating 55mm yellow or white tonal variation strips. Interlocks with MOD 4 and MOD 5 sections.

View MOD7 technical diagram (pdf)

DWG files (for use with Autodesk software) are available from our Downloads Page

Fixing Recommendations

For

fixing onto stone or concrete stairs, ensure that surface is sound and

level. Make good any worn or broken areas with rapid cement or epoxy repair

mortar.

For

fixing onto stone or concrete stairs, ensure that surface is sound and

level. Make good any worn or broken areas with rapid cement or epoxy repair

mortar.

Position Alispar on step. Spot through to mark with a 4mm dia masonry

drill. Lift off Alispar and drill 6mm dia hole where indicated

to take a red plug. Apply a layer of bedding compound (e.g. exterior grade

tile adhesive) to step and relay Alispar. Screw down with 4mm dia stainless

steel countersunk screws.

For steel stairs position Alispar on step, spot through with 4mm HSS drill bit. Lift Alispar off and drill steel through with 5mm HSS bit. Apply layer of insulation membrane (e.g. Bituthene). Use Countersunk machine screws, nyloc nuts and washers to fix.

For timber stairs ensure surface is flat and level. Use 4mm woodscrews.

Before

After